But I thought I'd issue an update on the Freedom 17 which we're doing stapless this time. We're also going with a rolling bevel versus a bead and cove. It's actually going pretty good and I'm having to come up with some creative clamping. But the strips are behaving and so far the strips where they meet each other are not showing any gapiosis as one would think.

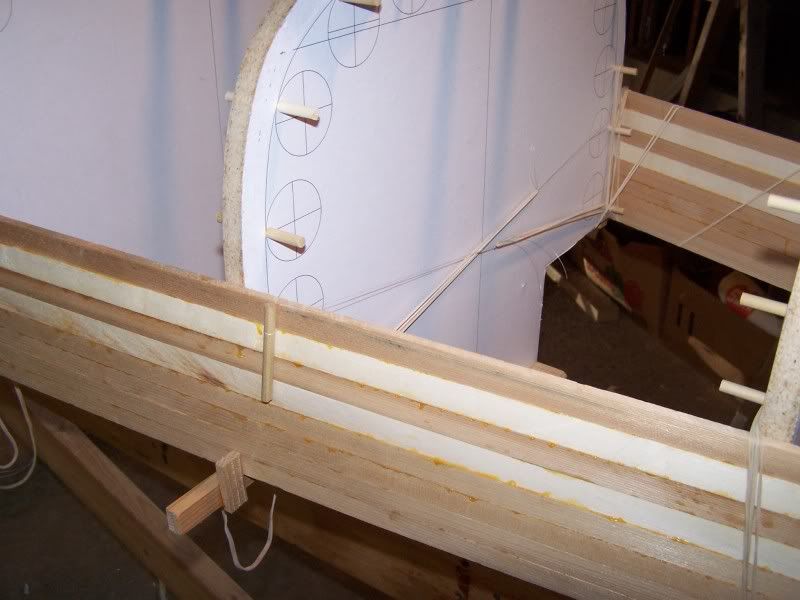

This first shot shows how the band clamping is doing it's job and it also shows how I've used fishing line and some short 1/4" dowels attached to rubber bands for tension to hold the hull to the forms where it needs to be "convinced".

The danglies there are just the breaks - hey it happens. After so many stretchings and wrappings against cedar the band will fail.

This shows the additional tension bands where they need to be used. Some areas the hull wants to pull away and some places the strips snug right in just fine. (yes the forms are fair) In order for the hull to be true and fair it MUST hold tight to the forms but I am bound and determined to go all stapless this time and this really isn't taking that much more time than when we built Chris' solo.

This one is "inside" the forms looking at the inside skin of the hull to give an idea of how the rubber bands are hugging the strips to the forms while the glue dries.

I've found in this humid Michigan weather that the hull moves considerably. So much so that even an experiment with hot glue (to tack the strips to the forms) did not hold due to the hull movement from humidity. The tension bands work remarkably well and the fishing line passing between the strips leaves a negligible hole. I know right where it is and I still cannot see it.

I've seen some users here use the fishing line method to do what I'm doing with the rubber bands but since I'm not doing bead and cove I was sure the fishing line wrapping hard over the strip edges would leave permanent marks. I'm sure that can't happen with bead and cove strips. Or very little.

Strips are beveled on a jig - I don't even try to freehand it. The jig is very simple and basically just holds the strip on edge while you ride your low angle block plane down a stepped rail.

It will need to be closed in before winter and unfortunately I will have to raise the hull to the roof trusses to get the cars in for the Michigan winter. I just can't handle the fiberglass and epoxy at this time. But she'll be ready in the spring for final fairing and fiberglass.

Thanks for looking!