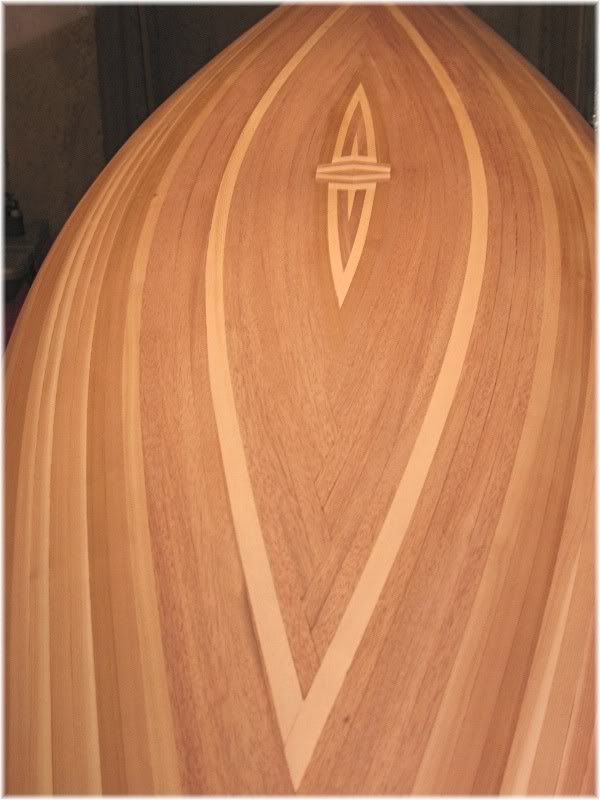

Football stripping

Perform a test. Take and glue up 3 panels, 12" x 12". One with wood strips lightly tacked together with dabs of glue. The second edge glued strips, fully glued and clamped together. the third, use bead and cove strips tightly glued. Fiberglass all three with the same cloth and epoxy, both sides. Take them to a press and subject them to pressure in the middle of the form and see what makes them fail. My suspicion is that the wood provides some strength, but the difference between a well glued wood/fiberglass panel and a poorly glued wood/fiberglass panel is not that much different, assuming the fiberglass is done the same way. Or, better stated the vast majority of the strength comes from the fiberglass expoxy layers and the wood contributes only slightly.

-

BearLeeAlive

- Posts: 196

- Joined: Tue Aug 18, 2009 7:00 pm

My thoughts (and this coming from someone yet to build but does understand structural strength) are that the wood itself only contributes a small amount of strength, but instead creates a additional strength with the fiberglass inner and outer wall be separating the two. Within reason, the further these two layers are apart, the more stiffness (rigidity) it would give the hull.

Just thinkin'.

Just thinkin'.

-JIM-

A big mistake people make is thinking the strength of a strp built hull comes from the epoxy and glass. A canoe built with no wood core and laminated with fiberglass and epoxy will weigh a lot more. Glass boats are heavy. You would need a total of 45oz. of cloth to build a canoe with just glass , according to a book I have on building composite canoes. If you did it with kevlar you still have more cloth weight then a stripper.Wood adds strength.

I’m not sure that wood adds strength as much as rigidity of form and flexibility. Glass by itself is brittle. Adding any cushioning material between two layers of glass increases the puncture resistance by absorbing the impact and helping to retain shape. The fibers in the wood provide that. Think of a composite car bumper. The shell by itself is garbage but add foam and it becomes very impact resistant even reforming the original shape in light impacts. Wood gives me an easily shaped material to put glass on. It’s pretty too. Matthew

Think of a cross section of the hull being like a "I" beam. You have two flanges (fiberglass) and the web (cedar). Additional width (web) increases strength or load carrying capacity. One side (flange) is in compression and the other side (flange) is in tension. The web is basically a spacer...

Joe "Woodchuck" Gledhill

Garden City, MI

Garden City, MI

This test would be hard to do preserving your assuptions, because the wet out of epoxy would (and does) penetrate and fill all the gaps and interstices anyway, resulting in a solidly glued structure either way. In fact, I've always thought that if one could prevent or control the dip through, and figure out a way to plank the strips without any glue at all, that might be the ideal way to do it. I'll not try it because I wouldn't even want to contemplate dealing with a lot of soak thru and runs of cured epoxy when it came to work on the inside.Tom in MN wrote:Perform a test. Take and glue up 3 panels, 12" x 12". One with wood strips lightly tacked together with dabs of glue. The second edge glued strips, fully glued and clamped together. the third, use bead and cove strips tightly glued. Fiberglass all three with the same cloth and epoxy, both sides. Take them to a press and subject them to pressure in the middle of the form and see what makes them fail. My suspicion is that the wood provides some strength, but the difference between a well glued wood/fiberglass panel and a poorly glued wood/fiberglass panel is not that much different, assuming the fiberglass is done the same way. Or, better stated the vast majority of the strength comes from the fiberglass expoxy layers and the wood contributes only slightly.

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

Björn Thomasson builds his boats with square-edge strips and uses no glue except at the inner stems. More about his technique here: http://www.thomassondesign.com/building ... _deck.aspx

Big Woody,,,,that's the same "herringbone" pattern I used and I was very pleased with it...

On a second note, it's hard for me to believe that some people don't think that the wood

strips add strenght to the canoe, It adds alot of strenght. Wood is the strongest natural building material on the face of this Earth, (pound for pound), if it was invented today it would be called the "mircale" fiber. I took my strip canoe down a river with Class III rapids and 4 flt waterfalls and the guys I was with (including me) were suprised at how will the canoe "helded-up". Do not underestimate the strength of a wood strip fiberglass canoe, probably the best , light weight, strongest water craft around.

On a second note, it's hard for me to believe that some people don't think that the wood

strips add strenght to the canoe, It adds alot of strenght. Wood is the strongest natural building material on the face of this Earth, (pound for pound), if it was invented today it would be called the "mircale" fiber. I took my strip canoe down a river with Class III rapids and 4 flt waterfalls and the guys I was with (including me) were suprised at how will the canoe "helded-up". Do not underestimate the strength of a wood strip fiberglass canoe, probably the best , light weight, strongest water craft around.

I asked about the strength of football patterns because I do believe that the pattern and the wood makes a difference to the strength of the canoe. The I beam analogy doesn’t quite do it for me but I will accept it. I think of a strip canoe more like a cars windshield. The glass in a windshield provides the barrier and strength while the soft plastic between the layers of glass provide flexibility and the resulting sandwich is stronger than each of the components separately. Safety glass can take tremendous impact and force because of the flexible layer in the middle. Wood in a canoe provides the same flexibility. In an I Beam the web is the strength and the top and bottom are platforms to build/hang on. It’s the sandwich of the canoe that is strong. Mmmmm sammich.

Personally I think the herringbone pattern should be the strongest because all of the strip ends are staggered and the strips are bent. The arc of the strip is stronger than a flat strip, eggshell principle. Even though all of the ends are close to the centerline, the herringbone itself weaves it together providing more strength than butt joints. I can’t let go of the perceived weakness of having a centerline cut from one end to the other right to the top of the stems. The end to end football (Hazen) is not much better however I think is should be less prone to racking.

But yeah, I understand the strength is in the fiberglass. I owned a fiberglass boat. Easy to repair but also easy to damage. Too easy to damage.

I guess my big problem is that I’m not building just a coffee table. I want a coffee table that I can abuse the crap out of.

Matthew

Personally I think the herringbone pattern should be the strongest because all of the strip ends are staggered and the strips are bent. The arc of the strip is stronger than a flat strip, eggshell principle. Even though all of the ends are close to the centerline, the herringbone itself weaves it together providing more strength than butt joints. I can’t let go of the perceived weakness of having a centerline cut from one end to the other right to the top of the stems. The end to end football (Hazen) is not much better however I think is should be less prone to racking.

But yeah, I understand the strength is in the fiberglass. I owned a fiberglass boat. Easy to repair but also easy to damage. Too easy to damage.

I guess my big problem is that I’m not building just a coffee table. I want a coffee table that I can abuse the crap out of.

Matthew