Canoe Build in Arkansas

Canoe Build in Arkansas

Im having a difficult time locating Cedar Lumber in Arkansas, anyone know of a source.

I can't wait to get started.

I can't wait to get started.

Re: Canoe Build in Arkansas

I wish I could offer a solution for you, but I am not located anywhere near you.

I would offer that sourcing the long, clear lengths of wood is often difficult for a lot of folks. My first build I literally spent a month on the hunt. I finally reconciled myself that I wasn't going to find the 18' lengths I was after .... I was ready to head to the local big box store for 16' cedar decking (plan was to work around the knots and waste), when I also realized that I was going to need to revisit all the places I had checked, because I had changed the material spec.

I went to a local specialty yard (my preferred source) to look over their 16' material, which is the standard longest length. While looking over the stock, I noticed a few boards that were a lot longer than the rest and they were labelled 17', 18' and 19' ... all in clear cedar. I asked why I was told they didn't stock anything longer than 16' when I called ... the explanation was "we don't stock longer lengths, some come with the shipment and we set them aside as specialty".

I have built 2 canoes using lumber from a source that initially told me they didn't have the stock ...

The moral of this story is that if you aren't actually going to the supplier and checking it out (talking with them), you may miss what you are looking for and also those folks are probably the best ones to point you in another direction if they can't supply what you need.

Having said all that, this forum is pretty well spread out and you will likely get a few other responses for your region.

Good luck on your build, make sure you post pics and progress ... you are in for a great adventure.

Brian

I would offer that sourcing the long, clear lengths of wood is often difficult for a lot of folks. My first build I literally spent a month on the hunt. I finally reconciled myself that I wasn't going to find the 18' lengths I was after .... I was ready to head to the local big box store for 16' cedar decking (plan was to work around the knots and waste), when I also realized that I was going to need to revisit all the places I had checked, because I had changed the material spec.

I went to a local specialty yard (my preferred source) to look over their 16' material, which is the standard longest length. While looking over the stock, I noticed a few boards that were a lot longer than the rest and they were labelled 17', 18' and 19' ... all in clear cedar. I asked why I was told they didn't stock anything longer than 16' when I called ... the explanation was "we don't stock longer lengths, some come with the shipment and we set them aside as specialty".

I have built 2 canoes using lumber from a source that initially told me they didn't have the stock ...

The moral of this story is that if you aren't actually going to the supplier and checking it out (talking with them), you may miss what you are looking for and also those folks are probably the best ones to point you in another direction if they can't supply what you need.

Having said all that, this forum is pretty well spread out and you will likely get a few other responses for your region.

Good luck on your build, make sure you post pics and progress ... you are in for a great adventure.

Brian

Re: Canoe Build in Arkansas

I live near St. Louis. If you have a Menards nearby, I was able to get cedar planking in various widths that was 13/16" thick and 10' or 12' long. By picking through their stacks, I was able to get boards that were 60-70% clear. It took a lot of work, but I scarf-ed together around the knots and got the lengths I needed for my Freedom 17.kiwimay wrote:Im having a difficult time locating Cedar Lumber in Arkansas, anyone know of a source.

I can't wait to get started.

Re: Canoe Build in Arkansas

I've bought soo much Western Red Cedar from Menards !

I always bought #3 and better 1x stock, 1"x12", 1x8, even 1x6"s. Decking seemed too wide of a strip for my liking, especially when stripping around the bilge.

Splicing strips right on the hull, is easy, especially if you bead and cove

I simply use a Butt joint. If you match strip colors, it's nearly invisible.

One spring clamp and a couple of scraps covered with tape.

I like a 2" spring clamp, as that allows me to start the next course right away. Once you lay on the next course, the bead and cove hold everything in place, and you can just keep going.

Just be sure to stagger your splices.

I love sorting lumber ! Home Depot, Menards. I'm always bringing home Cedar.

Look for flat sawn lumber. It produces your best strips !

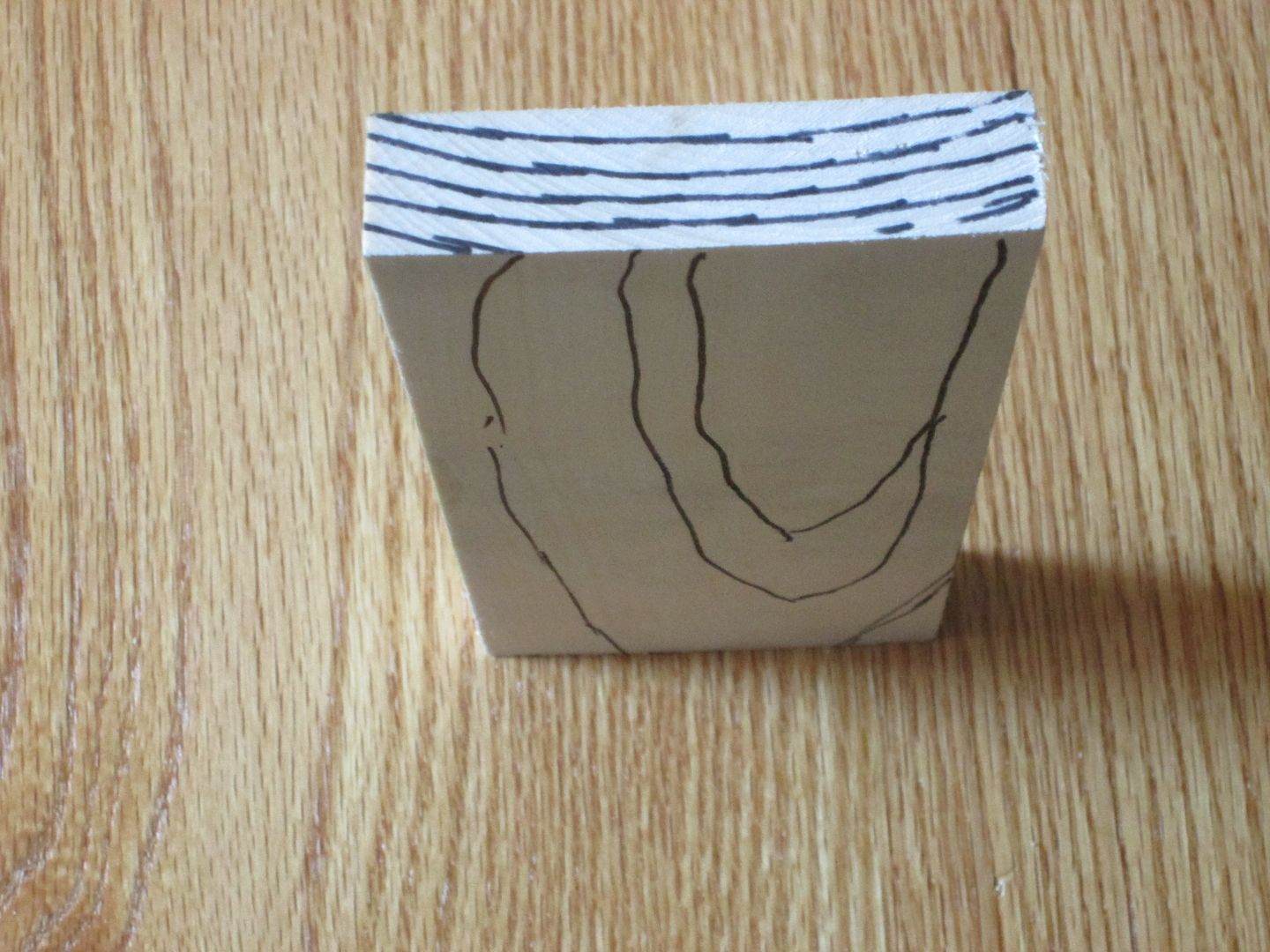

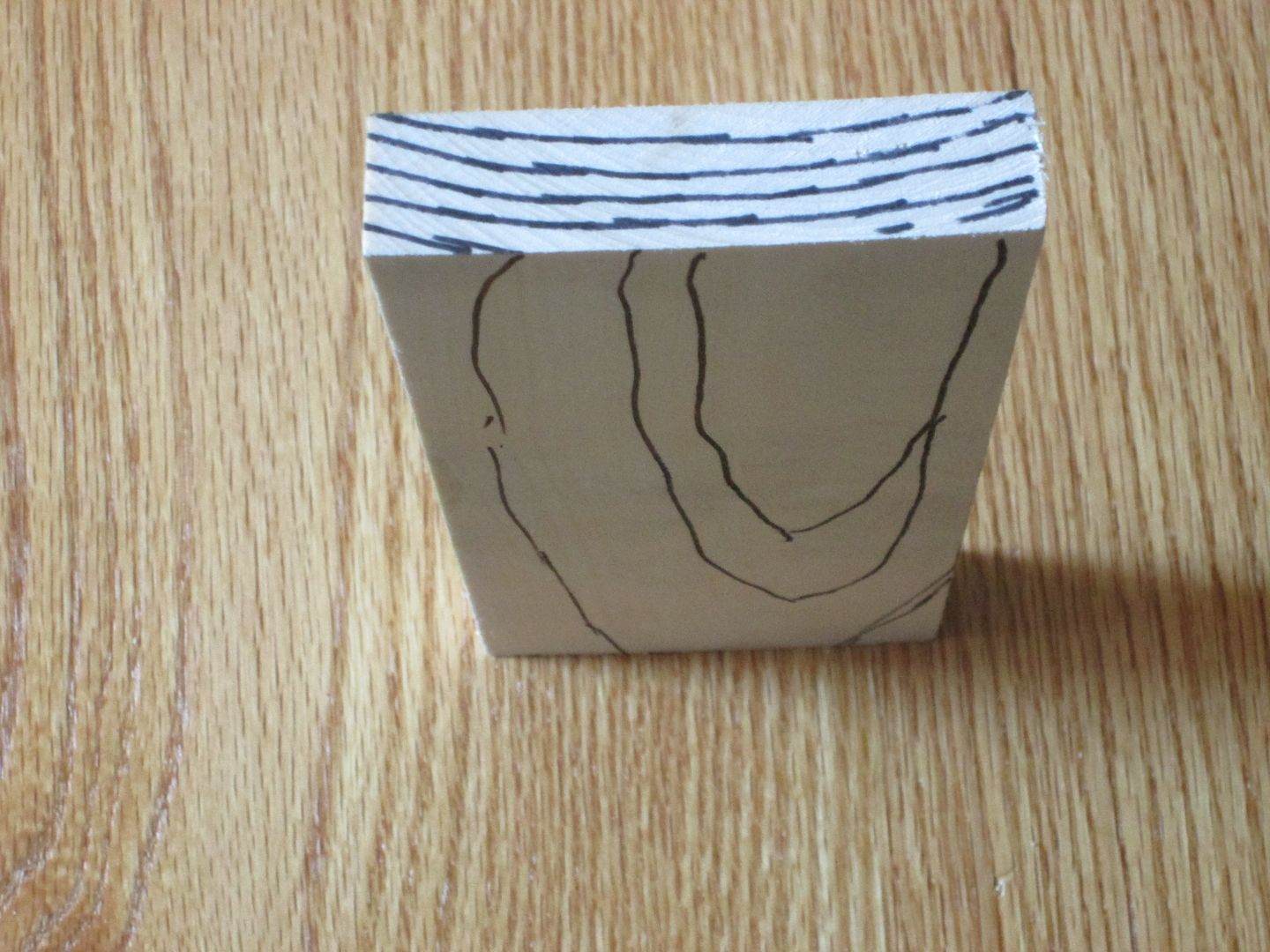

Here's an illustration.

Welcome Aboard kiwimay !

Jim

I always bought #3 and better 1x stock, 1"x12", 1x8, even 1x6"s. Decking seemed too wide of a strip for my liking, especially when stripping around the bilge.

Splicing strips right on the hull, is easy, especially if you bead and cove

I simply use a Butt joint. If you match strip colors, it's nearly invisible.

One spring clamp and a couple of scraps covered with tape.

I like a 2" spring clamp, as that allows me to start the next course right away. Once you lay on the next course, the bead and cove hold everything in place, and you can just keep going.

Just be sure to stagger your splices.

I love sorting lumber ! Home Depot, Menards. I'm always bringing home Cedar.

Look for flat sawn lumber. It produces your best strips !

Here's an illustration.

Welcome Aboard kiwimay !

Jim

Keep your paddle wet and your seat dry!

-

Rehd Brown

- Posts: 148

- Joined: Sat Sep 08, 2007 8:23 pm

- Location: Fresno, California

Re: Canoe Build in Arkansas

Kiwimay

I have found, in two or three places over on the left coast, that while they don't stock the longer lengths, if you go in and talk to them and tell them what you are looking for, they can order special lengths. It's available somewhere and they usually don't stock it because it's not what folks are typically using in that region. The mills and wholesalers all ask higher prices for the longer boards, so if your local dealer says it's going to cost you a little more, rest assured, they are also paying a little more for it.

I stay away from the local lumber yards and look up "Hardwood" suppliers because they generally have everything or can get anything you want. Regular lumber yards and Big Box stores sell construction grade materials because that's their business and it's what the general public wants. Hardwood suppliers carry just about everything else because they sell to mostly commercial business'. However, as you have read above, you can scarf shorter boards together to make whatever lengths you desire and pay a little less for it

Rehd

I have found, in two or three places over on the left coast, that while they don't stock the longer lengths, if you go in and talk to them and tell them what you are looking for, they can order special lengths. It's available somewhere and they usually don't stock it because it's not what folks are typically using in that region. The mills and wholesalers all ask higher prices for the longer boards, so if your local dealer says it's going to cost you a little more, rest assured, they are also paying a little more for it.

I stay away from the local lumber yards and look up "Hardwood" suppliers because they generally have everything or can get anything you want. Regular lumber yards and Big Box stores sell construction grade materials because that's their business and it's what the general public wants. Hardwood suppliers carry just about everything else because they sell to mostly commercial business'. However, as you have read above, you can scarf shorter boards together to make whatever lengths you desire and pay a little less for it

Rehd

Re: Canoe Build in Arkansas

Thank you all.

I did call Meeks Lumber and they said they have Western Red Cedar up to 16' but id have to sort it.

Its a start and I can't wait.

I did call Meeks Lumber and they said they have Western Red Cedar up to 16' but id have to sort it.

Its a start and I can't wait.

Re: Canoe Build in Arkansas

Only drawback to ordering, is you may end up with quartersawn planks. Not what you want !

I'd go and sort in a heart beat !

A proper scarf, in my book, is a 10-1 ratio. That means you will throw away nearly a foot of lumber, when you scarf. Sarfing works ! Just not necessary.

Jim

I'd go and sort in a heart beat !

A proper scarf, in my book, is a 10-1 ratio. That means you will throw away nearly a foot of lumber, when you scarf. Sarfing works ! Just not necessary.

Jim

Keep your paddle wet and your seat dry!

Re: Canoe Build in Arkansas

On my last build I used white cedar, which isn't available in longer lengths, so I basically had to scarf everything I used.

I decided to just skarf the stock material, before I cut strips. That meant that I only had to do 1 joint for many strips. As far as the ratio goes, this isn't a structural joint (structural requires 8:1 or higher), you can use butt joints on the boat, but to be able to handle the strips you will need a better joint. I used 4:1 and it worked great. A lot less waste and I only had to do a few joints for the whole project. One note on this, for this method I recommend you use epoxy for these joints ... standard method, wet out with unthickened, followed by thickened, then join.

Doing the skarf joint on the stock material also gives somewhat better control of where the joints are on the strip, and by mixing the location of the skarf on the stock, you get a variety of joint locations which makes it easier to stagger the joints.

This also makes doing the book matching process easier, as you have full length strips straight off the stock material with similar variations/patterns formed as you cut each strip.

You can get creative if you want, mixing lighter and darker pieces on the same strip, highlighting the different wood or try to match colours or accent the joints with coloured epoxy .... depending on your vision of the completed project, skarfing can be used as a design element for your project.

Just a few thoughts.

Brian

I decided to just skarf the stock material, before I cut strips. That meant that I only had to do 1 joint for many strips. As far as the ratio goes, this isn't a structural joint (structural requires 8:1 or higher), you can use butt joints on the boat, but to be able to handle the strips you will need a better joint. I used 4:1 and it worked great. A lot less waste and I only had to do a few joints for the whole project. One note on this, for this method I recommend you use epoxy for these joints ... standard method, wet out with unthickened, followed by thickened, then join.

Doing the skarf joint on the stock material also gives somewhat better control of where the joints are on the strip, and by mixing the location of the skarf on the stock, you get a variety of joint locations which makes it easier to stagger the joints.

This also makes doing the book matching process easier, as you have full length strips straight off the stock material with similar variations/patterns formed as you cut each strip.

You can get creative if you want, mixing lighter and darker pieces on the same strip, highlighting the different wood or try to match colours or accent the joints with coloured epoxy .... depending on your vision of the completed project, skarfing can be used as a design element for your project.

Just a few thoughts.

Brian

Re: Canoe Build in Arkansas

I'd have to agree that for strips, a 4-1 ratio should be fine ! As Brian recommends.

I was thinking more on the lines of my gunnels, which I go 10-1, or more.

Which ever way you choose, Bead and Cove by all means !

Jim

I was thinking more on the lines of my gunnels, which I go 10-1, or more.

Which ever way you choose, Bead and Cove by all means !

Jim

Keep your paddle wet and your seat dry!

-

joanbarrett

- Posts: 3

- Joined: Mon May 10, 2004 1:36 pm

Western red cedar source

Ted and I work hard to source and supply the very best strips available. We ship all over the US. It is a small but vital part of our business and helps support things like this Builders Forum. We get our cedar from Vancouver Island - it is carefully selected and dried then shipped to Ontario where Ron Frenette mills it and packages it keeping all the strips and boards in order.

Many people tell us that if they had known the difficulty locating good cedar they would have just bought from us in the first place.

You cannot beat our quality and careful machining.

Wish we sold more but we also understand that folks like to save money and do the process themselves.

We would appreciate it if people using this forum would at least acknowledge our products and the good service we provide.

Please let us know if you would like a quote.

best regards - Joan

Many people tell us that if they had known the difficulty locating good cedar they would have just bought from us in the first place.

You cannot beat our quality and careful machining.

Wish we sold more but we also understand that folks like to save money and do the process themselves.

We would appreciate it if people using this forum would at least acknowledge our products and the good service we provide.

Please let us know if you would like a quote.

best regards - Joan

-

joanbarrett

- Posts: 3

- Joined: Mon May 10, 2004 1:36 pm

Re: Canoe Build in Arkansas

Western red cedar source

Postby joanbarrett » Tue Jan 10, 2017 2:17 pm

Ted and I work hard to source and supply the very best strips available. We ship all over the US. It is a small but vital part of our business and helps support things like this Builders Forum. We get our cedar from Vancouver Island - it is carefully selected and dried then shipped to Ontario where Ron Frenette mills it and packages it keeping all the strips and boards in order.

Many people tell us that if they had known the difficulty locating good cedar they would have just bought from us in the first place.

You cannot beat our quality and careful machining.

Wish we sold more but we also understand that folks like to save money and do the process themselves.

We would appreciate it if people using this forum would at least acknowledge our products and the good service we provide.

Please let us know if you would like a quote.

best regards - Joan

joanbarrett

Posts: 1

Joined: Mon May 10, 2004 6:36 pm

Postby joanbarrett » Tue Jan 10, 2017 2:17 pm

Ted and I work hard to source and supply the very best strips available. We ship all over the US. It is a small but vital part of our business and helps support things like this Builders Forum. We get our cedar from Vancouver Island - it is carefully selected and dried then shipped to Ontario where Ron Frenette mills it and packages it keeping all the strips and boards in order.

Many people tell us that if they had known the difficulty locating good cedar they would have just bought from us in the first place.

You cannot beat our quality and careful machining.

Wish we sold more but we also understand that folks like to save money and do the process themselves.

We would appreciate it if people using this forum would at least acknowledge our products and the good service we provide.

Please let us know if you would like a quote.

best regards - Joan

joanbarrett

Posts: 1

Joined: Mon May 10, 2004 6:36 pm

Re: Canoe Build in Arkansas

Joan has a good point, in that there are more options for the strips than making them yourself.

Setting up to make your own strips has a specific cost in time and money for the build. I suspect that sourcing materials, setting up to cut the strips, then cutting strips and milling the bead and cove could quite easily chew up 2-3 weeks of build time (minimum). The narrow saw blades (cutting strips), bead and cove cutters, router table with sufficient infeed and outfeed capability, could run a builder $100-$300 (depending on what you already have in the shop or can readily borrow).

If the goal is to build a canoe, for whatever purpose and that will likely be the the end of canoe building for you, then buying the strips makes sense. You save time, money and a lot of frustration sourcing suitable wood, in truth, I think preparing strips is a "pre project" all its own ... and you need to evaluate why you want to make them yourself.

If you want to get the project started sooner, you could also skip preparing the actual station molds by buying the CNC versions, which will cost you more, but gets you started 1-2 weeks sooner. Once you factor in that buying the premade molds gets you the plans, wood and finished stations, they are actually are pretty reasonable.

If you enjoy woodworking and the challenge of wrangling wood ... there is likely no way to dissuade you from taking on all of the tasks. My first set of strips were OK, took close to 2 months start to finish (sourcing to finished strips), they weren't the quality of the Bear Mountain ones, but it was the process I enjoyed .... it was making lots of sawdust, which is what woodworking is all about. I also didn't have a hard project deadline, and sourced new blades, cutters etc. for a cost approaching $300 ... so budget and timeline were not an issue ... which it is for a lot of folks. Just to make this paragraph clear, for the first boat, the total cost of the wood and cutters (not including time) for me exceeded the cost of buying the strips. Obviously, if you are planning on more than one boat, the setup costs are already made, so this means you realize a significant savings on strip production moving forward.

I figure there is a solid case to buy the strips premade, and even to get the premade molds, for those folks who would like to just get on with building a canoe without all the preparation required if you make the strips and molds yourself.

Brian

Setting up to make your own strips has a specific cost in time and money for the build. I suspect that sourcing materials, setting up to cut the strips, then cutting strips and milling the bead and cove could quite easily chew up 2-3 weeks of build time (minimum). The narrow saw blades (cutting strips), bead and cove cutters, router table with sufficient infeed and outfeed capability, could run a builder $100-$300 (depending on what you already have in the shop or can readily borrow).

If the goal is to build a canoe, for whatever purpose and that will likely be the the end of canoe building for you, then buying the strips makes sense. You save time, money and a lot of frustration sourcing suitable wood, in truth, I think preparing strips is a "pre project" all its own ... and you need to evaluate why you want to make them yourself.

If you want to get the project started sooner, you could also skip preparing the actual station molds by buying the CNC versions, which will cost you more, but gets you started 1-2 weeks sooner. Once you factor in that buying the premade molds gets you the plans, wood and finished stations, they are actually are pretty reasonable.

If you enjoy woodworking and the challenge of wrangling wood ... there is likely no way to dissuade you from taking on all of the tasks. My first set of strips were OK, took close to 2 months start to finish (sourcing to finished strips), they weren't the quality of the Bear Mountain ones, but it was the process I enjoyed .... it was making lots of sawdust, which is what woodworking is all about. I also didn't have a hard project deadline, and sourced new blades, cutters etc. for a cost approaching $300 ... so budget and timeline were not an issue ... which it is for a lot of folks. Just to make this paragraph clear, for the first boat, the total cost of the wood and cutters (not including time) for me exceeded the cost of buying the strips. Obviously, if you are planning on more than one boat, the setup costs are already made, so this means you realize a significant savings on strip production moving forward.

I figure there is a solid case to buy the strips premade, and even to get the premade molds, for those folks who would like to just get on with building a canoe without all the preparation required if you make the strips and molds yourself.

Brian