Bottom protection

-

Ben

Bottom protection

I was at a sport/vacation show this weekend and one of the spray-in truck bedliner companies(Line-X or Rhino, don't remember which) had a picture of a canoe that had had the bottom sprayed with their product. The canoe was red and the coating was color matched. To get to the point - has anyone done this with success on a stripper? I am not sure if you can get a clear coating of this product, but if you just did below waterline and went with black, this may be acceptable. They had a smooth product, unlike the rough texture that is normally found in a truck bed. How much weight would this add? Adhere to the epoxy okay? Need a coat of varnish? Feel free to poke holes in this, but sounds like it could be a decent idea...

It would increase yor boat in weight.

It would slow your boat down.

May want to think about a second (football shaped) fiberglass coat on the bottom.

Your call,

Doug

It would slow your boat down.

May want to think about a second (football shaped) fiberglass coat on the bottom.

Your call,

Doug

"Some people hear the song in the quiet mist of a cold morning..... But for other people the song is loudest in the evening when they are sitting in front of a tent, basking in the camp fire's warmth. This is when I hear it loudest ...." BM

Any additional coating will add weight. You might want to ask an applicator how much this would add. I also don't know and can't comment on the friction and laminar flow characteristics of the coating. I would however suggest a lighter color than black. One aspect of graphiting a hull bottom that has caused me to shy away from it is the black color. I am afraid if it is left in hot summer sun for any period of time it would get hot enough to cause glue creep and/or epoxy/glass problems.

Thought I'd post an update to this question. I searched the site for some mention of aluminum powder (West 420) but found none. A colleague who has much more experience with composites than I (who has some, at least) suggested a skim coat on the football with the above mentioned 420 for abrasion resistance and hardness, instead of graphite. It's light, lighter in color, and hard. It looks like a good idea, though I might be concerned about creating a stress riser at the edge. Anybody hear of/ tried this?

I don't expect (!) to be shooting any major rapids, but will probably paddle in some shallow, rocky spots. Thanks.

I don't expect (!) to be shooting any major rapids, but will probably paddle in some shallow, rocky spots. Thanks.

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

Mac McCarthy uses the aluminum powder on his boats to protect them from oyster shells. However, I have also read that this coating results in a slightly pitted surface and the "pits" show signs of corrosion after some usage in saltwater.

So, we have conflicting information on this product. Perhaps someone else knows more about it.

So, we have conflicting information on this product. Perhaps someone else knows more about it.

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

Another update...

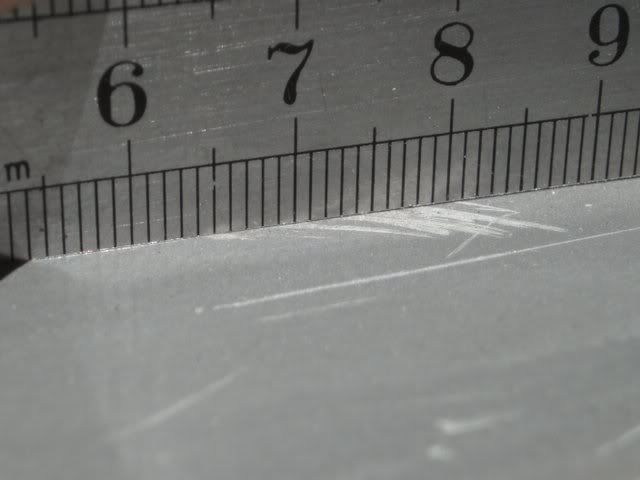

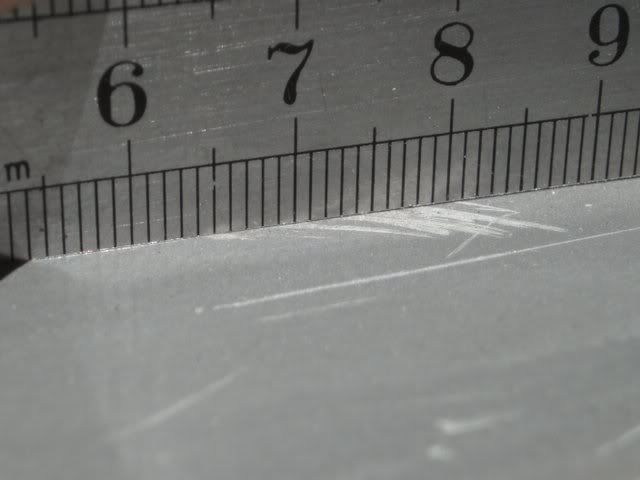

I coated the bottom of this Oughtred Beaver canoe with a second layer of 6 oz. cloth and a coat of epoxy thickened with aluminum powder.

I beat it up a bit on purpose by stepping out while it was grounded and swiveling on a gravel bank (with about 200 lbs point loading it).

The subsequent scratches were pretty insignificant...

So I do think that this aluminum approach is worth doing for extra hardness and abrasion resistance. It's not an especially pretty finish, but I plan on painting the outside anyway. By the way, I haven't been able to find anyone else who's built this design, but it seems pretty fast with that fine entry. Of course the recurved bow means you fight a bit to keep it headed upwind.

I coated the bottom of this Oughtred Beaver canoe with a second layer of 6 oz. cloth and a coat of epoxy thickened with aluminum powder.

I beat it up a bit on purpose by stepping out while it was grounded and swiveling on a gravel bank (with about 200 lbs point loading it).

The subsequent scratches were pretty insignificant...

So I do think that this aluminum approach is worth doing for extra hardness and abrasion resistance. It's not an especially pretty finish, but I plan on painting the outside anyway. By the way, I haven't been able to find anyone else who's built this design, but it seems pretty fast with that fine entry. Of course the recurved bow means you fight a bit to keep it headed upwind.