Ran into some issues last year with trying stapless method of only rubber bands. Try as I might the rubber bands were not holding the strips tight to the forms. Even hot glue was not holding the strips to the forms and was messy, time consuming etc. (could be wrong glue used too).

Money ran out (unemployed still) and temperatures went down (unheated garage for a workshop) so I had most of a winter to think this over.

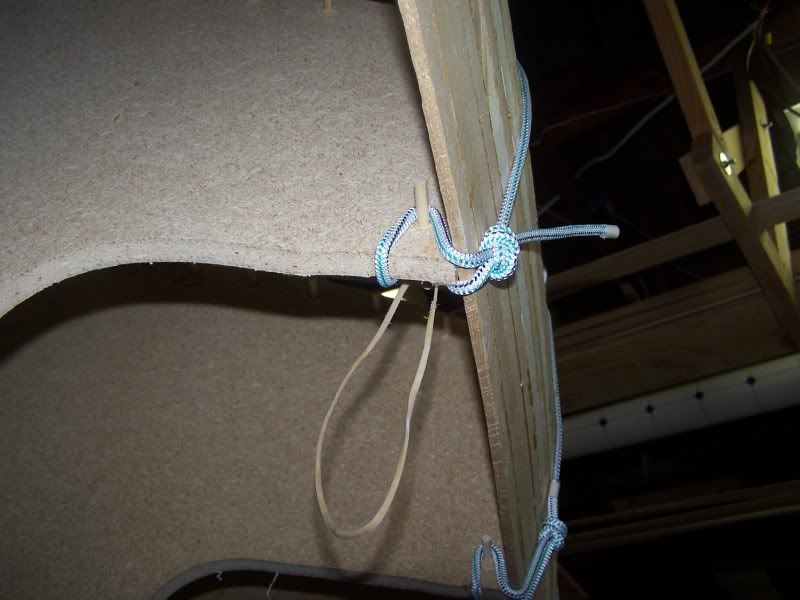

The rubber band Idea is not new and is explained in other areas of this board. But the idea for the bungee cord clamping to the forms was borrowed from Bear Mountain Boats' stapless kit. Frankly I couldn't afford it but it looked like a great idea. But their idea was for bead and cove strips and would be difficult to use on rolling bevel without damaging the "corners" of the strips.

So I stayed with the rolling bevel but kinda borrowed their idea of clamping the hull to the forms.

If you have a drill press (or a Shopsmith) drill some 1/4" holes around the perimeter of the forms about a fist distance apart. These will contain 1/4" dowels which hold the rubber bands. This is a little extra effort but you'll get a lot of mileage out of doing this later on.

Important note! I did staple the beginning strip to the hull forms to keep the above strips from sliding off the bottom of the form. The gunnels will cover it anyway so I figured why not.

The bands will give you a LOT of grief when adding new strips unless you do something to hold the bands up and away from the hull forms. This is where some 2.5" PVC pipe comes in handy. The pipe sections go under the bands so the strips can be slipped in and out along the length of the canoe. Ten foot section of PVC pipe was around $6 at a local big box store.

The neat thing about this is the glued strips with the rubber bands get bungee clamped to the hull forms and then the pipes get slid over to the other side to slip in the next strip. Which increases band pressure on the newly glued strips and further presses them against the hull forms.

Strips get dry fit and checked for proper splice location...

Extra bonus; the bands actually hold up the new strips while you run your glue line.

Functional shots of attaching the bands to the forms;

Final shot showing rubber bands in use and bungee clamps in place.