Uni-wale?

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

- Patricks Dad

- Posts: 1476

- Joined: Wed Oct 13, 2004 1:11 pm

- Location: Warrenville, Illinois

-

BearLeeAlive

- Posts: 196

- Joined: Tue Aug 18, 2009 7:00 pm

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

- Patricks Dad

- Posts: 1476

- Joined: Wed Oct 13, 2004 1:11 pm

- Location: Warrenville, Illinois

Glen, Moonman, those both look good. I've got several months to ponder. I'll post what I end up doing (on both Uni-wale and yoke topics).

But, while I'm thinking about it, I'll challenge all you guys (who are clearly much smarter and more creative than I am) to come up with a yoke solution that meets all of the requirements below (this is like utilzing spare CPU power across the globe to look for extrateresterials):

1. provides back support while not being used for portageing.

2. lightweight (I don't have a specific goal but you get the idea)

3. need not be detached from craft at any time during a trip (i.e., you can't lose it)

4. detachable for trips not requiring a yoke (or back support I guess). If you lose it, it's lost somewhere in your garage.

5. reconfigurable (if any reconfiguration is necessary) in 10 seconds max

6. option to attach to backpack strap for stability while portaging (while walking - not part of the 10 seconds).

7. what am I missing.?

OK, start thinking. to get you started, answer this: what's red and smells like blue paint?

But, while I'm thinking about it, I'll challenge all you guys (who are clearly much smarter and more creative than I am) to come up with a yoke solution that meets all of the requirements below (this is like utilzing spare CPU power across the globe to look for extrateresterials):

1. provides back support while not being used for portageing.

2. lightweight (I don't have a specific goal but you get the idea)

3. need not be detached from craft at any time during a trip (i.e., you can't lose it)

4. detachable for trips not requiring a yoke (or back support I guess). If you lose it, it's lost somewhere in your garage.

5. reconfigurable (if any reconfiguration is necessary) in 10 seconds max

6. option to attach to backpack strap for stability while portaging (while walking - not part of the 10 seconds).

7. what am I missing.?

OK, start thinking. to get you started, answer this: what's red and smells like blue paint?

- Glen Smith

- Posts: 3719

- Joined: Sat May 08, 2004 9:08 am

- Location: Baie-St-Paul, Quebec, Canada

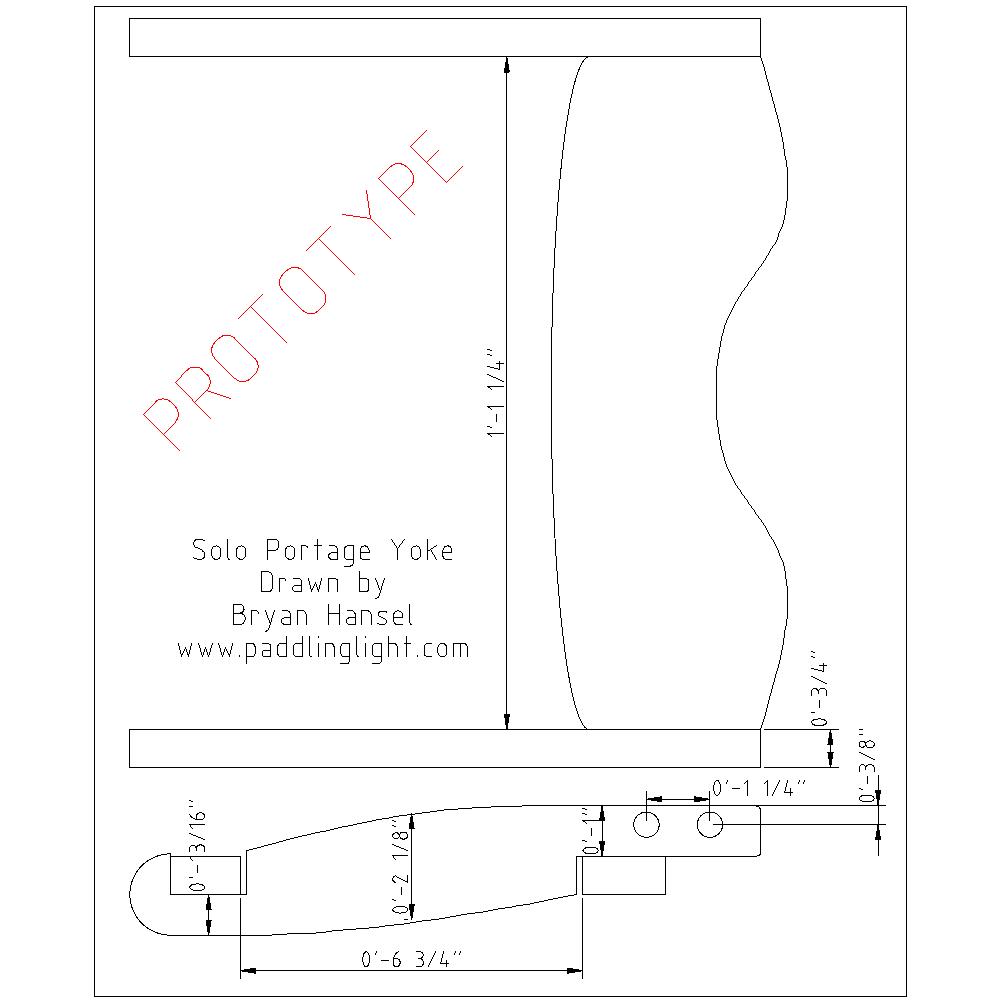

- Bryan Hansel

- Posts: 678

- Joined: Fri May 14, 2004 6:36 pm

- Location: Grand Marais, MN

- Contact:

That's a slick yoke. It looks so much simpler than a clamp-on yoke. Any idea of how much it weighs?Moonman wrote:Randy,

Here is a picture of a solo yoke solution I saw a few years ago. Maybe on this site or Canadian canoe routes. The yoke is not attached to the canoe permanently, the weight of the canoe holds it in place. You might vary something like this for your boat.

- Bryan Hansel

- Posts: 678

- Joined: Fri May 14, 2004 6:36 pm

- Location: Grand Marais, MN

- Contact:

This is one of the most beautiful wood canoes that I've seen. I love it. Did you vacuum bag the gunwales? What's the canoe's final weight? I don't suppose you have an online builder's log of this?mdevenyi wrote:My Freedom 17 employed some unconventional materials (for a cedar strip canoe) in an attempt to get the weight down to within ultra-light composite range:

The uni-wale was constructed of Core-Cell foam sheathed with carbon fiber sleeves and epoxy. A kerf was cut on the underside to accept the top edge of the sheer. Each gunwale came to 1.5 lbs. They were attached with aluminum truck box rivets from the inside, and 3M marine adhesive 4200 near the stems. All other trim--decks, cleats, seat sub-structure, yoke--were also made from Core-Cell/CF and vacuum-bagged:

Bryan,

The gunwales weren't vacuum bagged due to their awkward shape. They were a regular wet layup wrapped with long 2" wide strips of peel-ply to help squeeze out some of the excess epoxy and also leave them with a relatively smooth surface ready for a light sanding. The Core-Cell 2'x4'x1" sheet was cut into 4 foot long strips, routed with 1/2" and 1/4" round-over bits to shape the contour, a 3/16" kerf cut and finally scarf-joined end-to-end to reach approx. 18'.

The final weight of the completed canoe came in at 37 lbs, but that's with only 2 coats of varnish. The hull was made from 3/16" white cedar strips. It's due for a sanding this spring and a couple of fresh layers. I didn't have the time for an online builder's log, but did document most of the process with photos.

The gunwales weren't vacuum bagged due to their awkward shape. They were a regular wet layup wrapped with long 2" wide strips of peel-ply to help squeeze out some of the excess epoxy and also leave them with a relatively smooth surface ready for a light sanding. The Core-Cell 2'x4'x1" sheet was cut into 4 foot long strips, routed with 1/2" and 1/4" round-over bits to shape the contour, a 3/16" kerf cut and finally scarf-joined end-to-end to reach approx. 18'.

The final weight of the completed canoe came in at 37 lbs, but that's with only 2 coats of varnish. The hull was made from 3/16" white cedar strips. It's due for a sanding this spring and a couple of fresh layers. I didn't have the time for an online builder's log, but did document most of the process with photos.

- Bryan Hansel

- Posts: 678

- Joined: Fri May 14, 2004 6:36 pm

- Location: Grand Marais, MN

- Contact:

I'd love to see more photos of the build if you have time to post them online.

This guy uses tape with holes punched through it to laminate carbonfiber bike tubes. Do you think that could help improve your process or is it not worth the extra effort?

This guy uses tape with holes punched through it to laminate carbonfiber bike tubes. Do you think that could help improve your process or is it not worth the extra effort?

I think Moonman's yoke that hooks over the seat could meet all your requirements with minor modifications. You could add magnets so that it would stay in place while unsupported upside down. To make it convert to a back rest, you could make notches in the bottom of the yoke supports, and place a bar under the seat for the top end notches to engage. The same magnets could lock it into place. It would switch between positions in seconds, not fall out, but be easily removed.

Alan

- Bryan Hansel

- Posts: 678

- Joined: Fri May 14, 2004 6:36 pm

- Location: Grand Marais, MN

- Contact:

Guys,

I just want to make it clear that both those yokes I posted are not mine. I only posted the pics that I found interesting and saved from other posters over the years from various canoe boards. If I can find the original threads/names I will definitely credit the designers of those yokes.

Moonman.

I just want to make it clear that both those yokes I posted are not mine. I only posted the pics that I found interesting and saved from other posters over the years from various canoe boards. If I can find the original threads/names I will definitely credit the designers of those yokes.

Moonman.

One other variable I thought of re yoke design, was the different torque applied to the hull depending upon how the seat was mounted to the hull (for an integral yoke/seat combo, or something close to that).

If the seat was epoxied to the hull sides with cleats etc. I think the yoke could add a lot of torque to those glue up areas. This would be less so of course if the seat was hung from the gunwales (but then the gunwales need to be a bit beefier so maybe no uniwale without perhaps a gradual widening of the gunwale in the mounting area). Since I'll be using thinner gunwales on my eventual Freedom Solo build (uniwale or standard approach), I'll be mounting the seat directly to the hull so designs will have to reflect that.

Saying all that, I did have a couple design ideas/approaches. In one of his posts, Randy mentioned perhaps using a sliding seat to account for differing seating position versus yoke balance position. Another idea might be to not use a sliding seat but instead a sliding yoke. If the yoke was designed with rails that are secured under the seat with an aluminum bracket, then you could have the yoke in a 'back' position, under the seat, then a forward position, when you slide it out. Design challenges would be the sliding rails may need to be extra long so that once extended in the forward position, they still reach from front edge of seat to the back edge of seat (maintaining contact to both set of seat rails is important for strength and torque reasons). also, if mounted underneath, the weight of the canoe is 'hanging' from the yoke rails, instead of 'pushing down' on the yoke rails, with would be a preferable method.

So....maybe a better approach than the sliding yoke would be a 'hinged' yoke. with a design similar to the first pic I posted, you could have the yoke attached to the back edge of the seat. Right above the attachment point you have some sort of back support. when you need to portage, you lower the yoke (forwards) so that the actual yoke/neck cutout is now in the proper position. Design challenges here are that the yoke might sit up too high when in the up position, and perhaps a few others things as well.

Just a couple possible approaches off the top of my head.

Moonman.

If the seat was epoxied to the hull sides with cleats etc. I think the yoke could add a lot of torque to those glue up areas. This would be less so of course if the seat was hung from the gunwales (but then the gunwales need to be a bit beefier so maybe no uniwale without perhaps a gradual widening of the gunwale in the mounting area). Since I'll be using thinner gunwales on my eventual Freedom Solo build (uniwale or standard approach), I'll be mounting the seat directly to the hull so designs will have to reflect that.

Saying all that, I did have a couple design ideas/approaches. In one of his posts, Randy mentioned perhaps using a sliding seat to account for differing seating position versus yoke balance position. Another idea might be to not use a sliding seat but instead a sliding yoke. If the yoke was designed with rails that are secured under the seat with an aluminum bracket, then you could have the yoke in a 'back' position, under the seat, then a forward position, when you slide it out. Design challenges would be the sliding rails may need to be extra long so that once extended in the forward position, they still reach from front edge of seat to the back edge of seat (maintaining contact to both set of seat rails is important for strength and torque reasons). also, if mounted underneath, the weight of the canoe is 'hanging' from the yoke rails, instead of 'pushing down' on the yoke rails, with would be a preferable method.

So....maybe a better approach than the sliding yoke would be a 'hinged' yoke. with a design similar to the first pic I posted, you could have the yoke attached to the back edge of the seat. Right above the attachment point you have some sort of back support. when you need to portage, you lower the yoke (forwards) so that the actual yoke/neck cutout is now in the proper position. Design challenges here are that the yoke might sit up too high when in the up position, and perhaps a few others things as well.

Just a couple possible approaches off the top of my head.

Moonman.