the story so far......due to a lack of available space elsewhere, my build takes place in the back yard. the strongback lived on a concrete slab on top of heavy duty polytarp which covered everything in an envelope when not in use, like so:

the strongback and station moulds together weigh in at 130kg (about 286lb). nice and stable. no way that's gonna shift in a hurry, she'll be right mate!

well, we had storms and wind and it weathered it all.....untill we had a day of very strong gusts of wind, then *bang*! over it went. so... on to the damage:

since it's going to be primarily a solo craft, i've already decided which end will be the blunt end and which is the pointy end, so those were the port side images. and the starboard side (where the impact happened) follow:

the inside of the last picture:

the whole setup was too heavy to just lift back up again, so i had to jack up the edge of the strongback to get the side of the hull off the ground and remove the station moulds to remove the hull and get a better idea of the damage. first assessment was kindling. i threw a couple of spring clamps on the flappy stem end and was able to tape across the split on the port side and it went back together perfectly. weather was closing in so i had to get the broken hull under cover, where it sat on the ground. i sent a shout out to the forum, and to quote patrick's dad "I'd get it back on the molds as soon as possible. " wise words which i left late. after a week of it sitting on the ground with no support, the tape had come away, one of the two clamps fell off. the weather and the weekend were playing ball so i was able to get the hull out on the lawn where i proceeded to start repairs. i started with the stem. threw some wood glue on the stem and clamped the hull back on:

this went well, i decided to start repairing the crack at the other end to the stem with some wood glue in the open crack :

i fugured i could just tape it together like i had when it first broke. things didn't go together quite so neatly, and those words by patrick's dad came back to haunt me. the glue was drying and the bast thing i could manage was :

i managed to get the bit that i'd glued (which wasn't the whole split) sort of together reasonably well. this was clearly not the way to do this repair. while all this was happening, i took care of the strongback so it shouldn't being going anywhere this time (i hope) :

i installed the two stem stations, and strapped in the middle station and station 4s, and with some help and a lot of care got the flimsy hull back onto the strongback and secured the stations in the hull back on their blocks. that's when i noticed:

instead of a nice convex curve there was a concave dip in the bottom. to quote patrick's dad "I'd get it back on the molds as soon as possible."

yeh, you've heard this before, but i thought it was worth another mention...

after some warmth from the sun and installing the rest of the stations, the bottom is back the way it should be. the next step was to get the hull conforming to the stations and getting those splits closed. one option presented to me was to use long cable ties. these would be cheap, secure, and glue wouldn't stick to them. another option was luggage tie downs, which could be tightened down well and are easy to remove. a third option would have been to use the flat bungees that i used when i was stripping in the first place. aside from one pair of bungees, i didn't think they exerted enough pressure. the cable ties i nixed because where i am it's hard to get long cable ties and i already had enough tie downs on hand to do the job.

but before that, i decided to attack the sheer damage:

this was the very first strip i set down before i worked out what sequence of actions to follow, how much time i had and the use to tape between stations. hence it was never fully glued along the full length of the strip. i sanded what i could get to and laid a generous bead of glue :

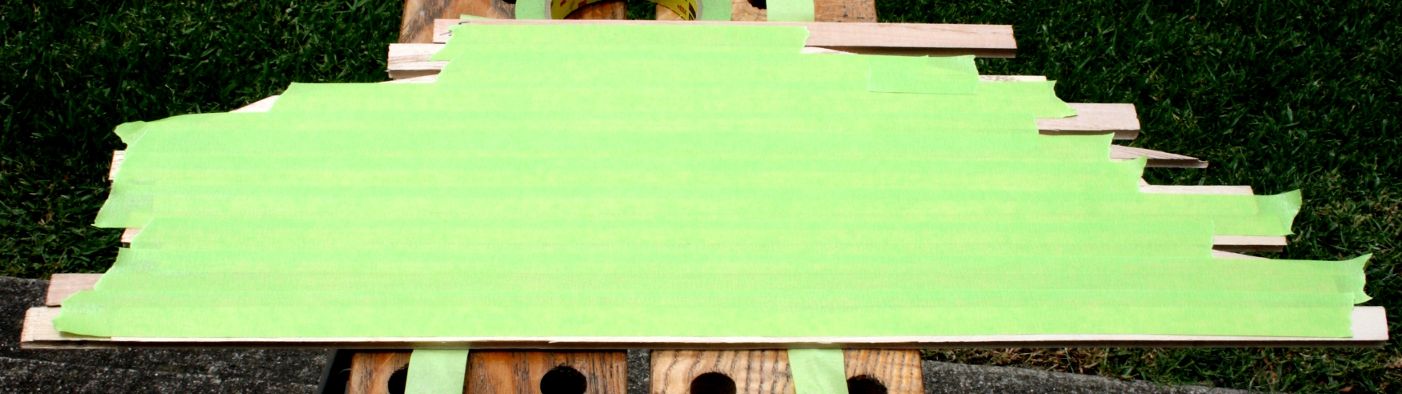

and taped it up:

once this had a chance to dry i proceeded with the strapping. starting with the starboard side, i've circled some of the spits because they came together so well they arn't obvious in the photos.:

and the port side:

i couldnt quite get the damage in the middle on that side to close completely:

well, that's what i'm up to so far. patrick's dad had suggested seeping unthickend epoxy into the cracks. i'll probably do that in some places, but when i saw the way those splits came together it made me think of my modelling days. another option to epoxy would be to put tape on the crack on the inside, and carefully seep cyanoacrylate adhesive such as hotstuff or zap into the cracks. most ca manufactures have a low viscosity formulation for good joint penetration amongst their stable of formulations. so as not to glue the straps i could do between the stations and finish off with the staps off another day. my only concern is that i'm not sure if the ca will show up as blotchy under the glass once its faired.