Margin of error for gaps?

-

jeromefloats

- Posts: 7

- Joined: Wed Jun 08, 2022 10:24 pm

Margin of error for gaps?

Hi all, I’m currently in the sanding phase of building a prospector (first build). I’ve filled all notable gaps and closed void with dust thickened epoxy as directed, but still seeing tiny ribbon thin cracks (not voids, just little divers you can barely get a finger nail into between some planking. This is likely due to bad/too deep of cove (will be getting a better router table for my next build). Will the epoxy fill this in when I put it on? I feel in order to achieve perfectly smooth I’ll almost be sanding right through my hull. I hope I didn’t come all this way for nothing.

Re: Margin of error for gaps?

Gaps or even staple holes will allow epoxy to weep away, through the hull.

If in doubt ? Do a seal coat.

Seal coats can help, as well as harm. ! After a seal coat if you choose ? Sand any dust specks, before laying on the cloth. These will create small voids, by lifting the cloth away from the hull.

Seal coats don't add weight. You end up using less epoxy, when you wet out the cloth.

Just be sure to add cloth, before waiting to long. I like to wait no more than 12 hrs.

Let you wet out coat cure at least 4 -6 hrs.

Apply fill coats, while the previous coat is still tacky ! This will greatly reduce runs and give you the clearest finish, as well as best bond.

Wish I was there to help glass. It's always the scariest part of building a canoe.

You will be fine ! Get a helping hand, that can at least properly mix resin for you !

Good Luck !

Jim

If in doubt ? Do a seal coat.

Seal coats can help, as well as harm. ! After a seal coat if you choose ? Sand any dust specks, before laying on the cloth. These will create small voids, by lifting the cloth away from the hull.

Seal coats don't add weight. You end up using less epoxy, when you wet out the cloth.

Just be sure to add cloth, before waiting to long. I like to wait no more than 12 hrs.

Let you wet out coat cure at least 4 -6 hrs.

Apply fill coats, while the previous coat is still tacky ! This will greatly reduce runs and give you the clearest finish, as well as best bond.

Wish I was there to help glass. It's always the scariest part of building a canoe.

You will be fine ! Get a helping hand, that can at least properly mix resin for you !

Good Luck !

Jim

Keep your paddle wet and your seat dry!

Re: Margin of error for gaps?

I agree with Jim's approach, but would caution against following anyone else's suggested timing , always check and follow your manufacturers instructions .... pretty sure this was Jim's intention.

You could do the seal coat, but it is an extra step, extra time to an already long day ... I might suggest a similar but easier path IMO. Prep/clean the hull, place the glass and get all the stuff ready to epoxy. When you add the epoxy, you usually have 20-30 minutes before stuff starts to kick and you squeegee off the excess.

If just make that initial coat a little thicker, you will have enough epoxy in place to accomplishing the filling in part and if you make sure of your timing to start the squeegee process, it shouldn't really move too much more from those gaps.

So just using a little extra epoxy and making sure not to squegee early can save you a step.

What do you think Jim?

Brian

You could do the seal coat, but it is an extra step, extra time to an already long day ... I might suggest a similar but easier path IMO. Prep/clean the hull, place the glass and get all the stuff ready to epoxy. When you add the epoxy, you usually have 20-30 minutes before stuff starts to kick and you squeegee off the excess.

If just make that initial coat a little thicker, you will have enough epoxy in place to accomplishing the filling in part and if you make sure of your timing to start the squeegee process, it shouldn't really move too much more from those gaps.

So just using a little extra epoxy and making sure not to squegee early can save you a step.

What do you think Jim?

Brian

Re: Margin of error for gaps?

Good advise Brian.

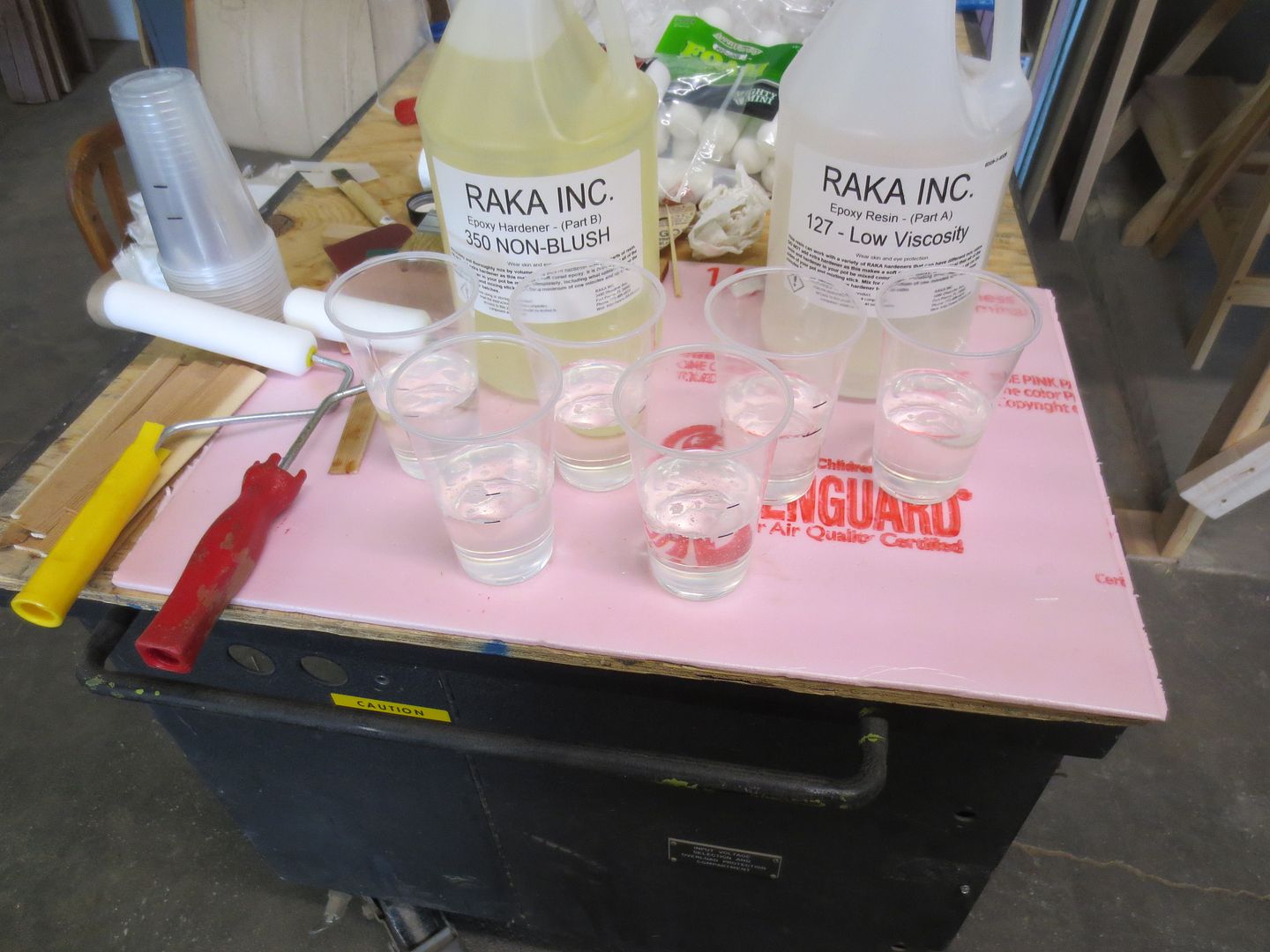

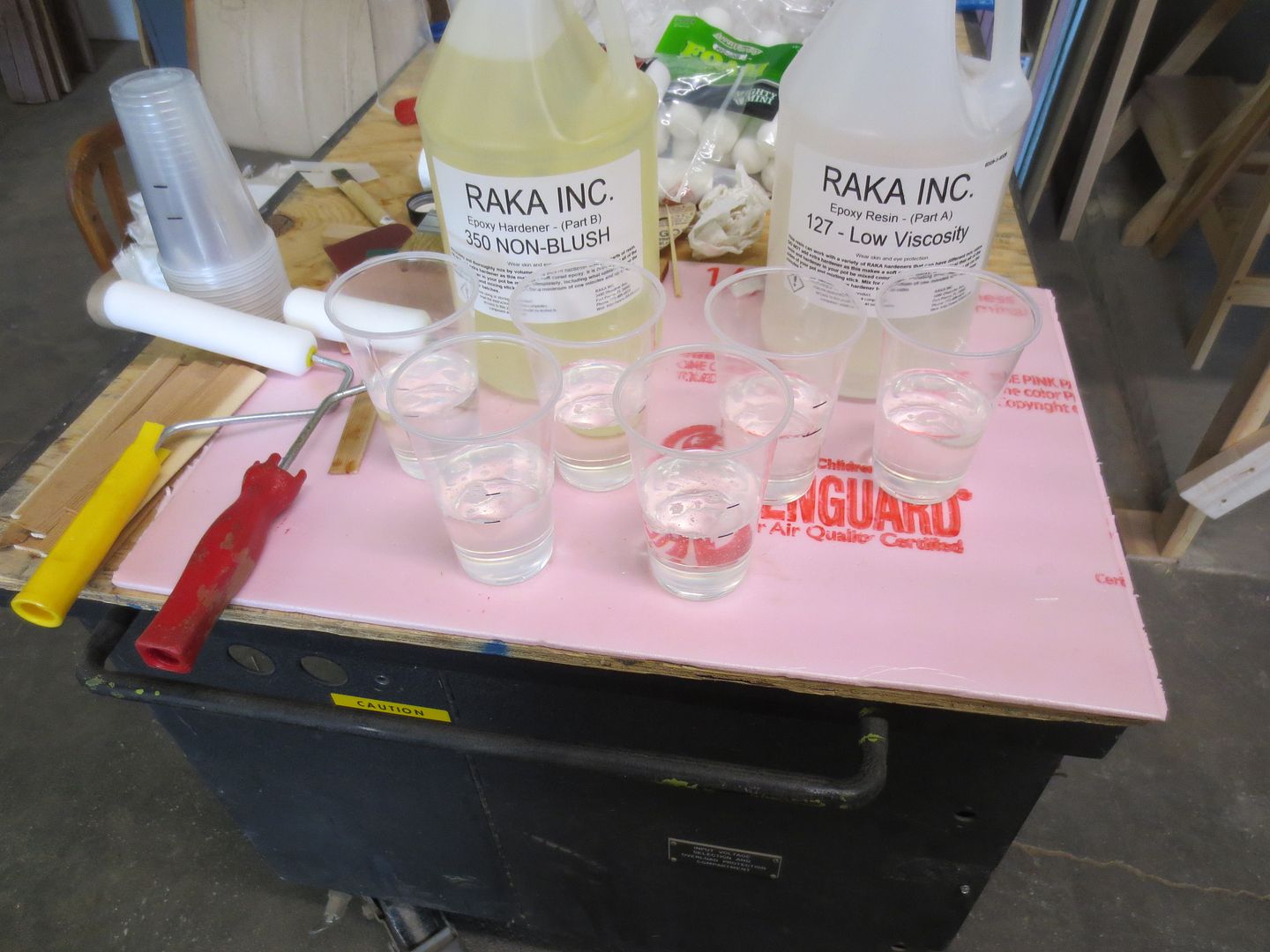

Another thought on epoxy. I never mix any bigger than a 9 oz cup, at a time.

I will prefill cups with resin, and then when needed, all I need do is add hardener, and mix.

This does two things, saves a little time, but more important, prevents me from making mix ratio mistakes.

Another thought on epoxy. I never mix any bigger than a 9 oz cup, at a time.

I will prefill cups with resin, and then when needed, all I need do is add hardener, and mix.

This does two things, saves a little time, but more important, prevents me from making mix ratio mistakes.

Keep your paddle wet and your seat dry!

-

jeromefloats

- Posts: 7

- Joined: Wed Jun 08, 2022 10:24 pm

Re: Margin of error for gaps?

Thank you all!!! I actually used some junk molds and a mistake stem and made a “mock up” mini hull section with scrap planking . I even gauged some nasty dents/cracks into it to see how well the epoxy would fill and used it for practice. I bought the good stuff (west 207 clear hardener) and in mid to upper 70s temps it proved to wet out / saturate very nicely. After getting some good 1/8 inch roller covers and making a bunch of pre measured cups I’m far less nervous proceeding. Cheers!!